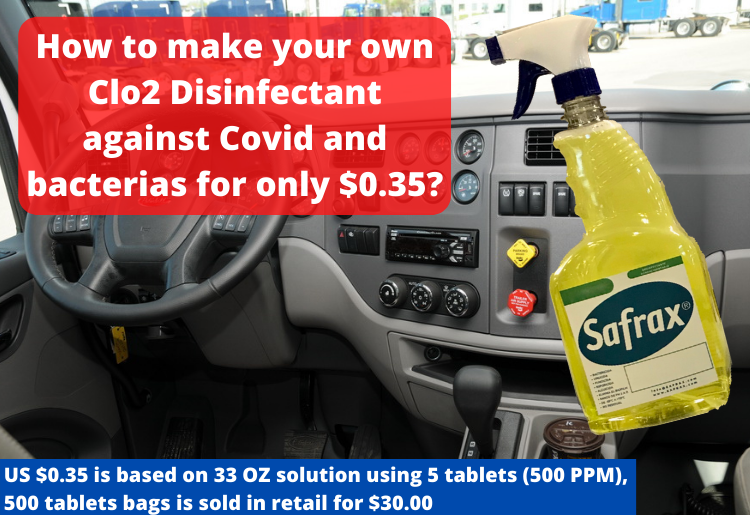

Chlorine Dioxide on Sanitizing / Disinfecting Trucks Cabs

Chlorine Dioxide Sanitizing Disinfecting Trucks Cabs Bed Bugs

Update on Sanitizing Disinfecting Trucks Cabin. In fall 2019, the Technology and Maintenance Council (TMC) of American Trucking Associations, www.tmc.trucking.org , pushed forward a Recommended Practice (RP) update approving the use of chlorine dioxide (ClO2) to combat Bed Bug infestation in a truck cab.

The Technology and Maintenance Council (TMC) S.4 Cab & Controls Study Group is charged with helping “improve the design and maintenance of cab components and systems to enhance the driver’s ability to properly, comfortably and economically operate highway vehicles.

Recommended Practice RP 443 showed ClO2 is “100% effective” in the removal of bed bugs, with the additional benefit of “complete odor removal.”

Recent updates proposed in March 2020 from TMC provide additional methods to further clean and sanitize a commercial truck cab. The study group issued these updates to help reduce the chance of spreading bacterial and viral germs, in particular the COVID-19 virus.

The updates focus on using chlorine dioxide (ClO2) as a cleaning agent, providing a full list of materials and methods for ensuring the sanitization of in-cab surfaces. In particular, the update features a step-by-step protocol for eliminating odors and disinfecting the cab, as well as best practices for mixing and applying a CIO2 sanitizing and disinfecting solution to in-cab surfaces.

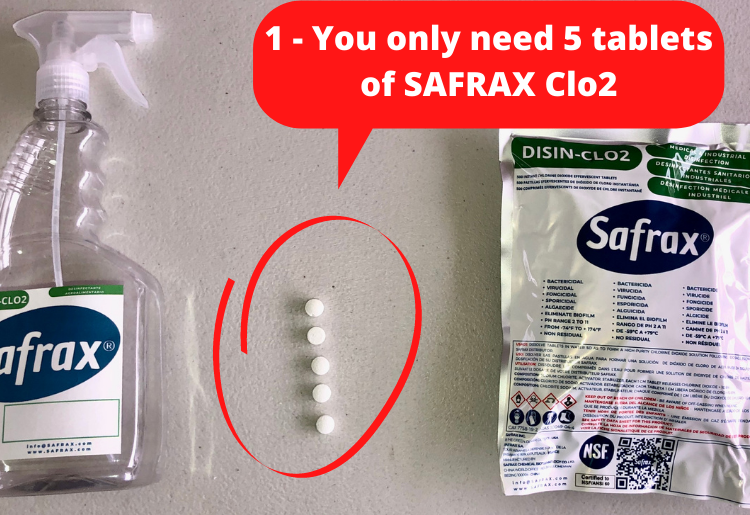

Chlorine Dioxide (Cl02) is a common disinfectant and odor eliminator, it is available in the form of tablets, and depending on the amount of water added, can be used in a vapor or liquid form.

“A number of industry experts were consulted, as well as U.S. EPA documents, to confirm the capabilities of the Chlorine Dioxide (CIO2) product and the effectiveness.”

said Mark Winchell, Director of National Accounts, Whiting Systems, Inc. Winchell is also the task force chair for the RP 443 update.

“We reopened the in-cab cleaning and deodorizing RP because there was a larger need for a select portion of our fleets to eradicate bed bug infestations. It required very high heat to eradicate [bed bug infestations]. The membership wanted a different method.”

While this RP update was already in progress, the RP 443 update came into the spotlight because of the additional benefits of safely and effectively eliminating pathogens such as the COVID-19 virus.

The proposed RP 443 update provides detailed instruction on both a thorough vapor cleaning process designed for more extensive, deep cleans of the cab, as well as a liquid treatment using a diluted solution for spot cleaning in high-traffic locations of the cab. The protocols are listed as Tractor Cab Odor Elimination And Disinfecting Protocol, and Liquid Sanitizing And Disinfecting Application Protocol, respectively, in the updated document.

“The vapor treatment is for complete treatment of the cab interior and could be used by itself or in conjunction with the liquid treatment – vapor first then liquid when used together.”

“The liquid treatment is performed to treat all surfaces or only high-touch (spot) surfaces. The vapor treatment would be performed to eliminate known odors and pathogens in a cab and would be performed as needed as a decontamination method. The liquid protocol would be done as a regular sanitizing/disinfecting method on a regular basis and when drivers/truck staff is changed.”

Mark Winchell confirmed the vapor treatment takes approximately five to eight hours, minimum. The protocol notes the process can be completed overnight.

“Treatment with the liquid product takes less than five minutes of labor and five minutes of dry time for a total of 10 minutes.”

Mark Winchell said.

Greg Johnsen, Regional Service Manager for Maverick Transportation LLC, a for-hire carrier headquartered in Little Rock, Ark., confirmed his fleet has implemented these methods for cleaning truck cabs. He sent an email to TMC Executive Director Robert Braswell, urging him and the group to consider adding another update to RP 443, this time endorsing ClO2 as effective as a coronavirus decontamination agent in the cab of a truck.

“I started digging into ClO2,” said Johnsen. “Upon reading the literature I could find online, I noticed this product will kill just about everything. This product is used heavily in the mold remediation industry as well as for removing smoke odors from fire damage.” (click here to see article on smoke odors removal)

“That this virus can be killed with soap and water is reported by the CDC. Viruses are a fragile organism outside the body, unlike mold spores or other spores which have a hard shell,” he said, noting that because it is effective against spore-forming bacteria, chlorine dioxide can also be used against anthrax. “As this product kills [spores], it seemed to be a natural progression in my opinion.”

Greg Johnsen started to sanitize 50 Maverick trucks and has since used it 23 times, “out of an abundance of caution,” he said. Two uses were prompted by drivers who reported feeling ill, but didn’t test positive for coronavirus. Chlorine Dioxide now, and going forward, is part of the Little Rock, Arkansas-based carrier’s regular cab sanitation practices.

“The original thought process was, if the driver gets sick we can use this to sanitize the truck,” he said. “Secondarily, we decided any time a driver leaves us, we’re going to use this process to prep the truck for the new driver out of an abundance of caution.”

“After Maverick leadership was brought up to speed on what this product and process could do, they made a decision out of an abundance of caution to use this process on any open unit prior to re-assignment to another driver.”

No Maverick drivers have tested positive for the COVID-19 virus at this time, noted Greg Johnsen.

A number of TMC members worked together to coordinate and ensure the proper techniques listed on these updates, including Winchell and Greg Johnsen. The RP updates also provide step-by-step instructions for tractor bed bug treatment, using the chlorine dioxide cleaning methods.

The RP 443 protocol for eradicating bed bugs using Chlorine Dioxide (ClO2):

The RP (Recommended Practice) protocol for eradicating bed bugs using ClO2 calls for the removal of all soft goods from the cab, including mattress and curtains, and sealing vents and door seams. Visible signage should be placed in the window warning not to enter the truck, and that a treatment is taking place.

A bucket with one gallon of water is placed on the bunk and another with one gallon of water on the floor with a battery-operated aerator placed into the buckets. Chlorine dioxide tablets are placed in each bucket, aerators turned on and the cab sealed, and left for five hours (24 hours if you don’t use an aerator). When the process is complete, all APU and cabin filters should be changed.

The RP 443 protocol update on cleaning and sanitizing truck cabs to prevent COVID-19 virus using Chlorine Dioxide (ClO2):

The protocol for the cab disinfection method, as posted to TMC is to open the refrigerator and all cabinets in the truck and sleeper berth, affix treatment signs to all exterior truck entry points and tape over exterior vents with non-marring tape to seal the cab.

Place one gallon of water in a pail, hang the battery-powered aerator on the edge and extend the hose with an air stone to the bottom.

Place the pail in the center of the truck on the floor, turn on the aerator and place a 100 gram ClO2 tablet into the pail and exit the truck cab, closing vents, doors and windows for five hours or until vapors cease and water is clear. Leaving overnight is ideal.

When the ClO2 solution has turned clear, it can be disposed of via discharge into a sanitary sewer. After treatment, flush the treated space with fresh air for up to one hour or until the odor has dissipated. This can be expedited using a fan or blower. After replacing the cabin air filter and bunk air filter, the truck can be returned to service.

“When used as a liquid, you spray it on a surface and walk away,” Johnsen said. “No need to wipe off or clean afterwards, as it is a disinfectant. We can do this vapor process for about $20 per truck. A small cost for keeping our driver and technician population safe.”

If sanitizing using ClO2 in liquid-form, open the cabinets and refrigerator, cleaning any highly soiled surfaces with an appropriate cleaner. Select a container size-appropriate for a ClO2 dilution level of 500 parts per million (ppm) – a 20 gram ClO2 tablet for a gallon of water, or a 100 gram ClO2 tablet for 5 gallons of water. Gently place the tablet into the water and allow two to three minutes to dissolve. Check the solution with a test strip to confirm its strength is between 250 ppm and 500 ppm, and fill a wet fogger or sprayer with the ClO2 solution. Wet fog or lightly spray all surfaces, ceiling to floor, allowing five minutes of wet contact time. No wiping or rinsing is required, and allow surfaces to dry before returning the truck to service.

Chlorine dioxide can be used in vapor- or a liquid-form, but as a liquid it is more fragile and its effectiveness is vulnerable to sunlight. Once diluted from tablet- to liquid-form, it has a shelf life of up to six months if stored correctly in an air-tight opaque container out of direct sunlight.

For in-cab treatment, the vapor and liquid methods can be combined, with the deeper cleaning vapor treatment being performed first and the liquid treatment applied afterward to surfaces and/or common touch points.

TMC has a COVID-19 community forum open to all TMC members. This forum provides full details on the processes and updates to RP 443 mentioned in this article.

SAFRAX is offering training and support for the Sanitizing Disinfecting of Trucks Cabin methods.